-

Table of Contents

Introduction

“The Anatomy of a Heavy Duty Dump Trailer: A Complete Guide” provides an extensive overview of the structure and functionality of heavy duty dump trailers. This comprehensive manual delves into the intricate details of these robust vehicles, including their chief parts, functioning principles, various types, and usage across different industries. The guide also offers valuable insights into maintenance practices for these machines to ensure their longevity and optimal performance. Whether you are in logistics or construction business or simply interested in understanding more about industrial machinery, this detailed guide serves as an exceptional resource to decode the complexities related to heavy-duty dump trailers.

Exploring the Structure of a Heavy Duty Dump Trailer: Full Details

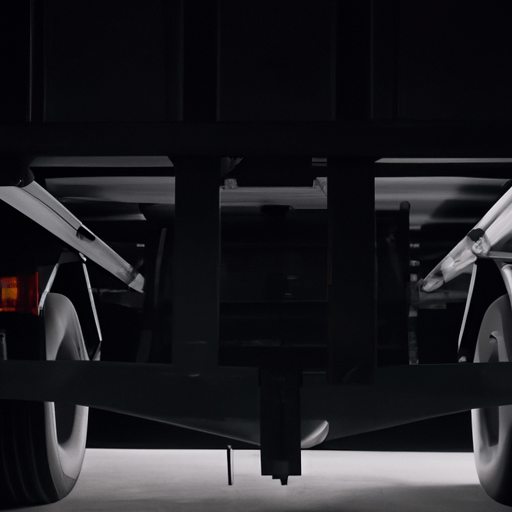

In the world of heavy load handling and transportation, the dump trailer holds an invincible position. A key component to various industries from construction to waste management, a heavy-duty dump trailer is designed meticulously for durability and efficiency. To better understand this powerful equipment, let’s take a closer look at its unique architectural design.

Beginning with the heart of a dump trailer: The frame. With unparalleled strength that can withhold monumental weight, it forms the core structure of this hefty machinery. It’s typically made up of high-quality iron or steel alloy ensuring resilience against stress and adverse conditions; whether it be traversing rugged terrains or accommodating tons worth payloads.

Right above the sturdy frame lies another crucial segment –-the dumping box or bed– tasked with carrying loads varying in size and density from rocks to scrap materials. Designed using sturdy metals such as hardened steel typically lined with anti-rust coating, these super-sized bins guarantee longevity amid constant cognizance to product damage prevention during loading/unloading operations.

Seamlessly integrated within this massive bin structure is an innovative mechanism known as hoist system; working remarkably similar to your physics’ class simple machine – levers! As you’d guess correctly, they’re here for lifting purposes which make offloading substantially easier than traditional means saving both time & resources significantly in return favoring project progression speed while minimizing risk factors involved during manual handling methods e.g., labor injuries etcetera

The familiar phrase “where there’s smoke there’s fire” rings true when discussing trucks’ exhaust pipes located just behind cabs emitting gas primarily composed carbon dioxide due combustion process occurring inside engine chambers resulting heat energy generation propelling wheels forward by delivering power required overcoming resistive forces encountered along roadways facilitating movement towards desired directions regardless external challenges faced may include steep slopes uneven surfaces alike proving vehicle efficiency overall truly remarkable feat human engineering brilliance brought forth technology allowed shaping civilizations throughout ages till today remains invaluable asset businesses likewise populace general too hence no surprise why they continue thrive market competing fiercely against alternatives available whether traditional advanced tech-driven options alike all thanks unique advantages offered – such as enhanced capacity, lowered operational cost and improved safety features.

Contributing to their reliability is a diverse set of tires that withstand the immense weight these trailers carry with utmost finesse. Usually six in number for standard models but can be more depending upon its size & payload demands; each offering firm treads adhering firmly on ground surfaces providing incessant traction control during movement thus ensuring stability alongside smooth handling maneuverability even when carrying maximum capacities.

Controlled by hydraulic systems which serve essential role within machinery allowing precise adjustments throughout operations giving operators full reign over required functionalities including effective brakes stopping vehicle time emergencies preventing accidents saving lives property alike adding another layer security resilience automotive giants like dump trailer further reinforces credibility highly revered industry sectors worldwide making an exemplar model efficiency durability safety combined one creating benchmark others follow strive achieving levels excellence achieved through rigorous design processes meticulous quality checks constant technological advancements put forth humanity’s never ending quest betterment societal needs wants ultimately leading towards increased productivity growth sustainability terms economy environment society large making invaluable contributor global progress advancement civilization marvel modern engineering magic!

In summary, this intricate threading of heavy-duty dump trailers’ vast structural integrity and functional superiority reaffirms its crucial importance across various industries showcasing how it redefines the standards of heavy load transportations as we know them today: A true testimony to human ingenuity at its best!

Understanding the Mechanics behind a Heavy Duty Dump Trailer: An In-depth Guide

If you’ve ever been intrigued by the mechanics of a heavy-duty dump trailer, then this complete guide will certainly pique your interest. There’s no denying that these hefty pieces of machinery are a testament to human ingenuity, built for extreme conditions and arduous tasks where standard trailers simply won’t suffice.

Now, how does such an impressive piece of equipment function? The anatomy of a heavy duty dump trailer is complex but can be understood when broken down into its key components: the chassis frame, hydraulic system, and the body.

First off is the chassis frame – think of it as the backbone which supports all other components and absorbs intense weight loads. Constructed from high-strength steel or alloy materials, it must withstand not only significant weights but also constant abrasion from rough terrains – making durability its top priority.

Next up in our mechanical exploration is arguably what makes this type of trailer incredibly unique – its hydraulic system. Once again proving itself as indispensable in bringing power to various industries, hydraulics plays an essential role here too; providing sufficient strength for lifting substantial weights even against gravity’s pull.

A closer look at how this works reveals something truly fascinating; dump trailers employ a telescopic cylinder mounted beneath their bed known as “hoist. This hoist operates very much like surgical syringes we might be more familiar with – fluid (usually oil) gets pushed under pressure within enclosed cylinders to create forceful movement upwards or tilted backward depending on configuration setting—effectively ‘dumping’ whatever load they bear without manual labor intervention.

Our last stop takes us to explore another crucial part—the dump body itself. Typically made out of reinforced steel plates welded together forming solid walls & floors—it’s usually rectangular-shaped maximizing volume capacity while maintaining stability during travel & dumping procedures.

Moreover, manufacturers also incorporate additional features enhancing user convenience & efficiency such as remote controls for operations (no driver needed), automatic tarp systems covering loads during transportation (prevents spillages & protects from weather elements), or even GPS tracking for fleet management applications.

Now, the body & chassis frame’s durable construction doesn’t come without its tradeoffs; heavy-duty dump trailers are notably heavier than standard ones making them more challenging to maneuver requiring experienced drivers behind their wheels. However, considering their indispensable role across various sectors such as construction, mining, waste management – the benefits they offer far outweigh any potential drawbacks.

In essence, the anatomy of a heavy-duty dump trailer is an intricate balance between strength and functionality. A well-designed trailer utilizes robust materials for enduring harsh environments and demanding tasks while incorporating advanced hydraulic systems for efficient equipment operation.

By understanding how these remarkable pieces of machinery work together in harmony, we can better appreciate not only their practicality but also marvel at how engineers continue pushing new boundaries—making our world revolve that bit easier every day.

Indeed, these hardworking titans’ sophisticated structure may seem daunting initially—but once delved deeper into what makes each part tick—it all starts making perfect sense. Through this guided tour around a heavy duty dump trailer’s insides—we hope you have gleaned some insight into this engineering genius—and perhaps ignited sparks of curiosity within you towards exploring similar wonders around us!

The Comprehensive Breakdown of a Heavy Duty Dump Trailer Construction

The heavy-duty dump trailer is the unsung hero of construction, landscaping, and demolition projects. While it might look like a simple piece of equipment, its design embodies ingenuity and function that make our workload significantly easier. Understanding this marvel isn’t just for engineers or machine enthusiasts; if you’re in any industry that regularly uses these trailers, having an intimate understanding of their anatomy can help increase efficiency and safety during operations.

At first glance, a heavy-duty dump trailer looks simplistic: A sturdy box sitting on top of wheels with hitches to connect it to your vehicle at one end. However, every component has been meticulously designed with specific functions in mind.

Starting from the ground up are tires specially built for immense loads. They’re not your regular vehicle tires; they’re larger and more robust to effectively handle sizable weights without buckling under pressure – almost literally! The axles too are custom-designed. Their length varies depending upon the size of the trailer itself as well as its load-bearing capacity.

Above these tires lies a thick steel chassis weld together to form an open rectangular structure supporting everything else above. This chassis cradles what we call ‘the bed’ — essentially where all material goes in a dump truck — typically made from hard-wearing materials like high-tensile steel or even harder alloys capable of resisting impact damage and wear from heaviness or roughness of whatever’s being transported.

A critical part often overlooked is the hydraulic hoist system that performs most heavy lifting here – both figuratively and literally speaking! It operates by using pressurized fluid (often oil) pushing against pistons inside cylinders which then lifts up one end allowing gravity do work emptying contents stored within onto wherever required.

Speaking about unloading material automatically raises conversation towards tipping angle – again another crucial element determining how efficiently stuff could be dumped out sideways or rearwardly based upon individual model designs allowing companies maximize operational efficacy optimizing appropriate dumping methodologies.

Once unloaded, the bed is lowered back down onto the chassis with precise control to prevent any damage that may be caused by sudden drops. This delicate operation is made possible thanks to shock absorbers which play their part relatively unsung but are irreplaceable nonetheless! They’re what provide damping function to stabilize motion when trailer goes over bumps or uneven terrain ensuring a smooth ride for loads carried within.

Finally, our heavy-duty dump trailer story wouldn’t be complete without paying homage to its hitching system making entire towing process feasible. Whether it’s a pintle hook or ball-and-socket type, these mechanisms allow safe secure coupling between trailers and vehicles letting them operate in tandem as one single unit which undoubtedly underline essence of whole setup by allowing prompt material transportation – effectively bridging gap between supply and demand!

In conclusion, each aspect of heavy duty dump trailer construction epitomizes a perfect blend of robust design principles fused together in unison creating something greater than sum of parts alone. Each component walks hand-in-hand with others – from tires that take weight brunt on themselves all way up towards hydraulic hoists doing hard lifting work above ground level. And while we might hardly give any thought usually about complexity involved behind scenes here; just remember every time you see one these mighty machines roaring past around corner: there’s more than meets eye indeed!

Q&A

- Question: What are the key parts of a heavy-duty dump trailer?

Answer: The key parts of a heavy-duty dump trailer include the frame, hydraulic lift system, box or bed, hitch, axles and wheels. -

Question: How does the hydraulic lift system work in a dump trailer?

Answer: The hydraulic lift system in a dump trailer works by using pressurized fluid to generate force that lifts and lowers the load-bearing box or bed. -

Question: Why is it important to understand the anatomy of a heavy duty dump-trailer?

Answer: Understanding the anatomy of a heavy-duty dump trailer allows for proper operation, maintenance, as well as troubleshooting potential issues which ensures safety and maximizes efficiency during loading/unloading processes.

Conclusion

In conclusion, the anatomy of a heavy-duty dump trailer is complex and designed for maximum efficiency and durability. It involves several key components like the chassis, body, hydraulics system, tailgate, tires amongst others that perform specific functions to ensure optimal operation. Understanding each part’s role in this machinery can improve operational efficiency while ensuring regular maintenance and safety protocols are adhered to.