Who can deny the pivotal role that hydraulic dump trailers play in our lives? Yet, when they falter, it can cause headaches.

This discussion's intent is to demystify the seemingly intimidating task of fixing these mechanical beasts. It'll navigate the maze of hydraulic systems, pumps, motors, and electrical aspects.

What if you could identify and rectify issues with ease? Stay tuned as we unravel the secrets of maintaining and troubleshooting hydraulic dump trailer systems.

Key Takeaways

- Regular inspection and maintenance of hydraulic systems can prevent leaks and excessive pressure build-up.

- Electrical issues in dump trailers can often be traced to wire connections, solenoids, and battery charge.

- Cylinder and hoist troubleshooting involves inspecting for damage, ensuring alignment, and testing under load.

- The motor and pump system requires regular cleaning, testing, and potential professional repair for optimal performance.

Preventative Maintenance Tips

Regularly inspecting and maintaining your hydraulic dump trailer system can prevent major mechanical issues, ensuring peak performance and extended lifespan of the system. Essential safety precautions include using the safety prop during system inspection and maintaining the box in an up position for leak prevention.

A low battery charge can contribute to pressure build-up and subsequent leaks, hence battery maintenance is vital. Opt for recommended chargers to prevent unnecessary strain on the battery.

Fluid level monitoring is a key aspect of routine system checks, with pressure gauge readings offering valuable operational insights. Regular cleaning of the hydraulic system and following manufacturer-recommended maintenance schedules can further enhance the system's reliability and performance.

Hydraulic System Issue Resolution

Identifying and fixing issues in the hydraulic system of a dump trailer is a critical aspect of maintenance. This often involves monitoring for leaks, excessive pressure, and valve conditions. Battery troubleshooting is a key step because a low charge can lead to pressure build-up, resulting in leaks.

One should also inspect for carbon buildup on solenoid contacts and check the condition of valve O-rings. Regularly monitoring fluid levels and pressure readings aids in early leak detection and prevention of tank cracks due to excessive pressure.

In the event of unresolved issues or stuck valves, seeking professional help is recommended. Proper maintenance and timely issue resolution not only guarantee the smooth operation of the dump trailer but also prolong its lifespan.

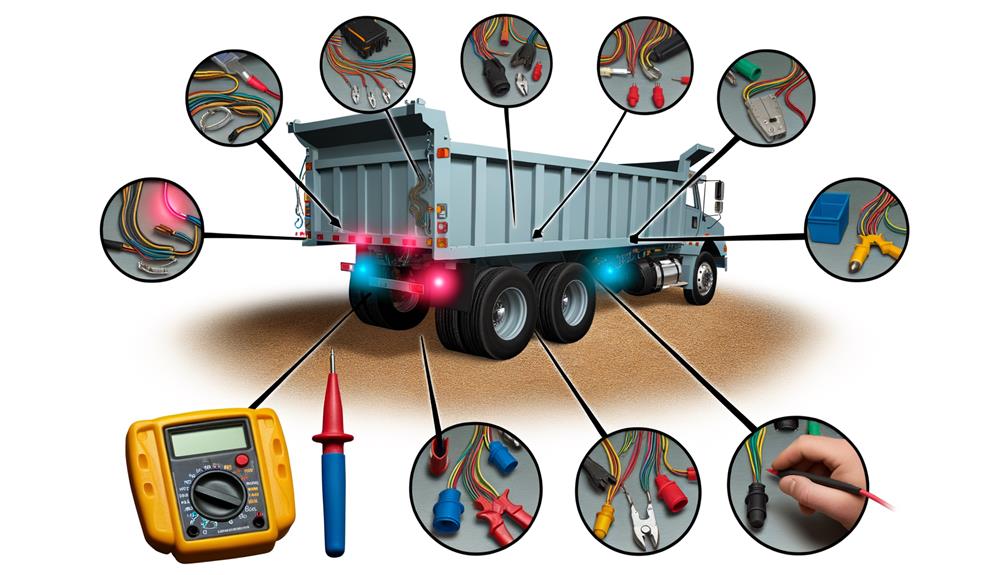

Electrical Troubleshooting Techniques

Often, maintaining an efficient hydraulic dump trailer system involves thorough electrical troubleshooting such as inspecting wire connections for cleanliness and tightness, and confirming power is reaching the coil. This process is vital for the system's longevity and performance.

Voltage testing and solenoid inspection are key components of this process. By performing these steps, one can identify potential problems before they escalate.

- Voltage testing ensures that the electrical system is receiving adequate power.

- Proper solenoid inspection can prevent failures in the hydraulic system.

- Regularly checking the cleanliness and tightness of wire connections can prevent electrical failures.

- Confirming power reaches the coil can help maintain the system's efficiency.

- Performing these steps can provide a sense of liberation, knowing that the system is in optimum condition.

This is the essence of electrical troubleshooting techniques for hydraulic dump trailer systems.

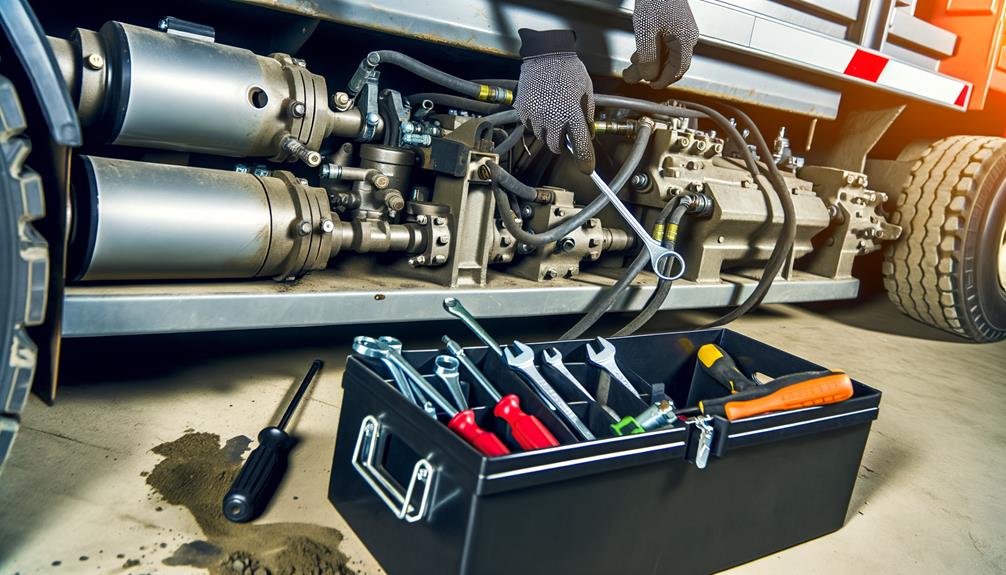

Cylinder and Hoist Maintenance

Maintaining the cylinders and hoist in your hydraulic dump trailer system is an important step to guarantee smooth and efficient operation. Regular cylinder inspection and maintenance prevent premature wear and damage. Check for any signs of pitting, scoring, or corrosion on the cylinder's surface, as well as for leaks in the seals.

Hoist alignment is essential to guarantee even lifting and lowering of the dump trailer. Misalignment can cause undue stress on the system, leading to potential damage. Regular lubrication of the hoist reduces friction, thereby enhancing its longevity and performance.

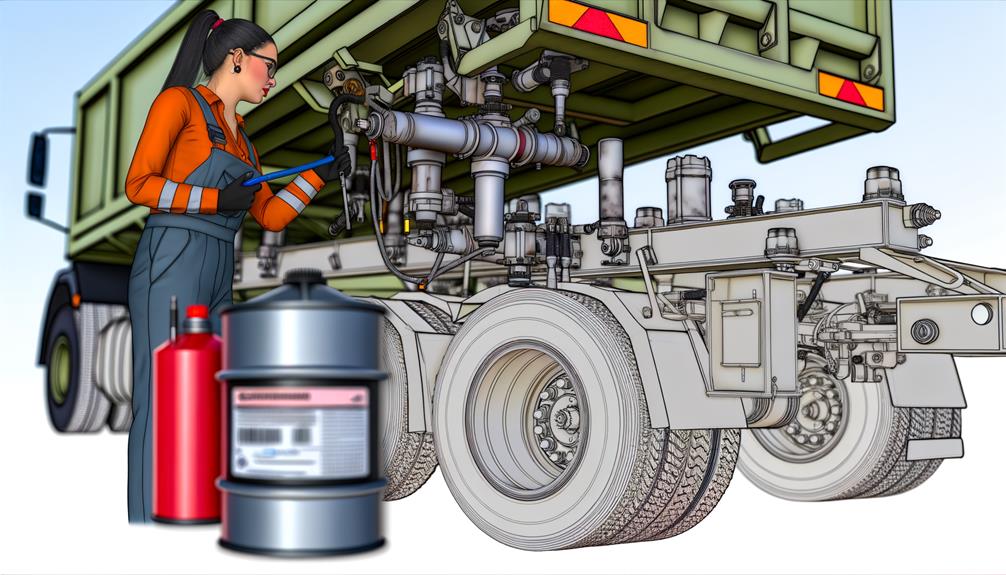

Pump System and Motor Care

Ensuring the proper care and operation of the pump system and motor is a critical aspect of hydraulic dump trailer maintenance. It's not just about preventing breakdowns, but also about enhancing performance and extending the lifespan of your equipment.

A proactive approach to motor troubleshooting techniques can save you time, money, and a lot of frustration.

Regular hydraulic fluid analysis allows you to catch problems early, before they escalate.

Consider pump system upgrades to keep your trailer running smoothly and efficiently.

Boost motor efficiency improvements to optimize power output and reduce energy consumption.

Frequently Asked Questions

What Safety Gear Should I Wear When Working on a Hydraulic Dump Trailer System?

When working on a hydraulic dump trailer system, they should wear durable safety gear. Protective clothing's importance can't be overstated – it safeguards from potential injuries, including those from leaks or pressure build-up.

How Often Should I Replace the Hydraulic Fluid in My Dump Trailer System?

They should replace the hydraulic fluid in their dump trailer system every year. Using the right fluid types and regular system cleaning guarantees peak performance and longevity of the hydraulic components.

What Are the Signs That My Hydraulic Dump Trailer Battery Needs to Be Replaced?

Signs that one's hydraulic dump trailer battery needs replacing include frequent leaks, low pressure readings, and decreased performance. Regular troubleshooting techniques can help determine battery lifespan and when it's time to invest in a new one.

What Are the Potential Hazards of Neglecting Regular Maintenance on a Hydraulic Dump Trailer System?

Neglecting regular maintenance on a hydraulic dump trailer system can lead to component damages, including leaks, cracks, and system failure. By implementing preventive measures, they'll avoid these issues and extend the system's lifespan.

Are There Any Specific Training or Certifications Required to Perform Repairs on a Hydraulic Dump Trailer System?

While specific certifications aren't mandatory, they're beneficial for credibility. Various training resources exist, offering insights on system repairs. This education enhances one's skill set, enabling them to tackle complex hydraulic dump trailer issues confidently.

Conclusion

In summary, regular preventative maintenance, adept hydraulic system troubleshooting, thorough electrical diagnostics, and diligent care of cylinder, hoist, pump system, and motor are vital for a well-functioning hydraulic dump trailer system.

By mastering these technical skills, one can guarantee efficient efficiency and longevity of their equipment.

This guide provides professionals and novices alike with the necessary knowledge to maintain smooth operation and to confidently tackle any issues that may arise.

5 thoughts on “How to Fix a Hydraulic Dump Trailer System”