In an era of horse-drawn carts, understanding the mechanics of a dump trailer's hydraulic system wouldn't have crossed anyone's mind. But today, it's a vital skill for many.

Often, operators face challenges with the hydraulic systems, resulting from issues like water in the fluid or incorrect pump mounting. But, what if there's more to these problems than meets the eye?

This discussion seeks to shed light on the oft-overlooked areas of dump trailer hydraulics, promising to provide insights that might just make you reconsider what you know about this complex system.

Key Takeaways

- Troubleshooting hydraulic issues in dump trailers involves examining the cylinder type, pump mounting, and potential water intrusion.

- Regular maintenance of the hydraulic screen and reservoir ensures optimal fluid flow and can help detect leaks in the system.

- Ensuring the cleanliness and functionality of the vent plug is essential in preventing hydraulic problems and maintaining system functionality.

- For safe and effective operation, always consult the equipment's manual and adhere strictly to safety instructions.

Hydraulic Cylinder and Pump Troubleshooting

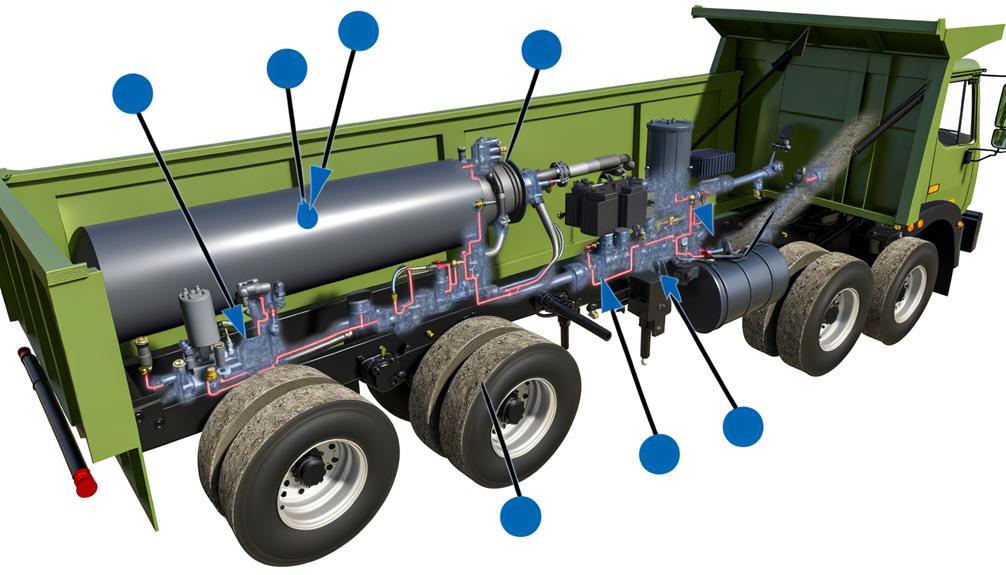

When addressing a hydraulic problem in a dump trailer, the first step typically involves identifying the type of hydraulic cylinder used – either a double action or single action telescopic. One must also discern the compatibility between the pump and the motor. Incompatibility often leads to inefficiencies and breakdowns.

Unaddressed issues may result in the double action cylinder functioning as a single action, thereby limiting its functionality. Additionally, hydraulic fluid contamination, often due to water infiltration, can severely compromise the effectiveness of the hydraulic system. Regular inspection of the fluid reservoir is crucial to detect and address this issue.

Hydraulic Screen and Reservoir Maintenance

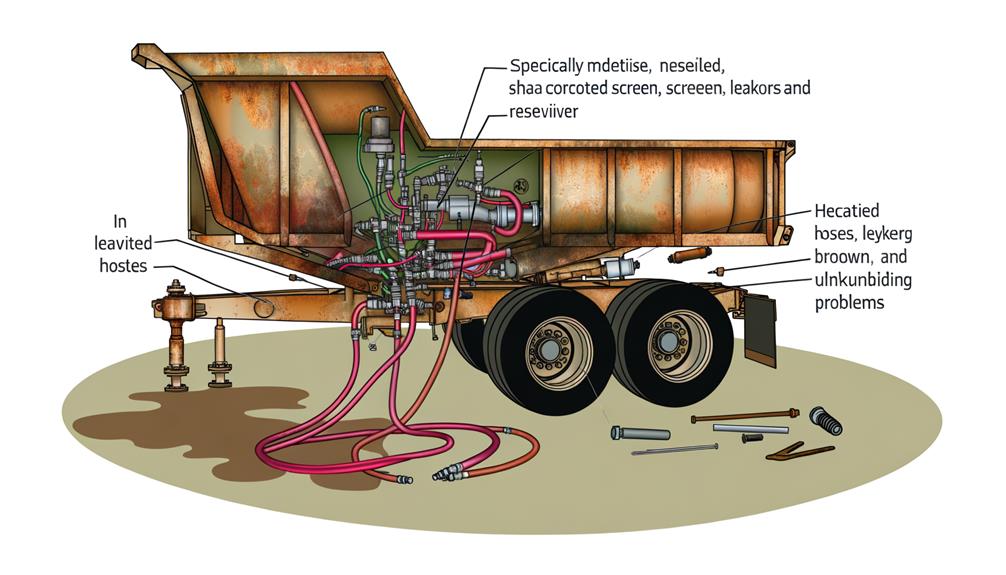

Ensuring top performance of your dump trailer, regular maintenance of the hydraulic screen and reservoir is essential to prevent obstructions and detect potential leaks. The process starts with screen cleaning to guarantee unimpeded fluid flow. The screen, often located at the base of the hydraulic tank, needs thorough inspection for any blockages. These obstructions often appear as a mayonnaise-like substance that can greatly hinder system performance.

Furthermore, constant monitoring of fluid levels in the reservoir is important. Changes in these levels during operation could indicate potential leaks within the tank. Some technicians even employ dye tracer and black light for leak detection.

Vent Plug and System Functionality

While maintaining your dump trailer's hydraulic system, one mustn't overlook the critical role of the vent plug in ensuring the best functionality. It acts as a silent sentinel, facilitating system venting solutions and maintaining the system's pressure balance.

Vent plug maintenance is therefore important; a clogged or dirty vent plug can lead to system malfunctions or reduced efficiency. Regular inspection and cleaning can prevent such issues. If a problem occurs, consider blowing out the vent plug to remove any obstructions.

Importance of Consultation and Safety

Just as the vent plug plays a significant role in maintaining the hydraulic system, so too does adherence to proper safety procedures and seeking professional consultation when operating machinery like dump trailers.

It's important to follow safety guidelines meticulously. They're not just rules, but informed measures designed to prevent accidents, guarantee peak performance, and prolong equipment lifespan. Missteps can lead to operational failures, or worse, personal injury.

Hence, the significance of consultation can't be overstressed. The benefits of consultation include access to expert advice, risk mitigation, and enhanced understanding of complex machinery operations. It fosters a culture of safety and proficiency, liberating operators from the constraints of ignorance and uncertainty.

Essentially, consultation and safety go hand in hand in ensuring efficient and risk-free operations.

Copyright, Privacy, and Third-Party Contributions

Exploring the territories of copyright and privacy, TractorByNet stands as a registered trademark of IMC Digital Universe, Inc., providing users with robust data control through its Privacy Manager. They've fortified their privacy measures, acknowledging the pivotal role of trademark acknowledgment in ensuring a secure virtual environment.

- TractorByNet's commitment to data control is visible in their Privacy Manager, designed to tailor user experiences.

- Its registered status as IMC Digital Universe, Inc.'s trademark ensures credibility and trust.

- Acknowledgment of trademarks is an essential part of their operation, promoting respect for intellectual property.

- They uphold high standards in dealing with third-party contributions, ensuring quality and relevance.

- Their approach to privacy and copyright issues exhibits a desire for a liberated yet responsible digital community.

Therefore, TractorByNet leads in demonstrating adequate user data control while respecting copyright and privacy.

Frequently Asked Questions

What Are Some Common Signs of Hydraulic Pump Failure in Dump Trailers?

They'll notice erratic operation, unusual noises, and decreased hydraulic power. Through "Pump Replacement Procedures" and "Hydraulic System Troubleshooting", they can determine if it's pump failure or another issue within the hydraulic system causing these symptoms.

How Often Should the Hydraulic Screen and Reservoir Be Maintained for Optimal Performance?

'Typically, one should inspect the hydraulic screen and reservoir every six months. Depending on hydraulic fluid types and usage, more frequent checks may be needed. Screen replacement techniques guarantee top-notch performance and system longevity.'

Are There Any Specific Cleaning Solutions Recommended for Maintaining the Vent Plug in Hydraulic Systems?

For vent plug maintenance, he's not restricted to specific hydraulic cleaning solutions. He can use mild soap and water, ensuring it's thoroughly dried afterwards. Avoid harsh chemicals that may damage the plug's material.

Are There Any Specific Safety Gears Recommended While Operating Hydraulic Systems in Dump Trailers?

'Indeed, safety gear's essential while operating hydraulic systems. Emphasizing safety training importance, one must conduct regular gear inspection routines. Helmets, safety glasses, gloves, and steel-toed boots are recommended. Always prioritize safety to prevent accidents.'

How Can I Use the Privacy Manager to Control My Data on Tractorbynet?

"He can navigate to 'Privacy Settings' within TractorByNet's platform. Here, he'll find options for data management. It's where he's able to control what information is shared and with whom. Always remember, his data is his freedom."

Conclusion

In optimal, effectively diagnosing and resolving dump trailer hydraulic problems necessitates a thorough understanding of cylinder/pump troubleshooting, screen/reservoir maintenance, and system functionality.

It's critical to verify clean vent plugs and adhere strictly to safety procedures. Consulting experts and leveraging third-party contributions are invaluable in this complex process.

Remember, maintaining your hydraulic system's optimal performance isn't just about fixing issues but also about proactive, meticulous maintenance.