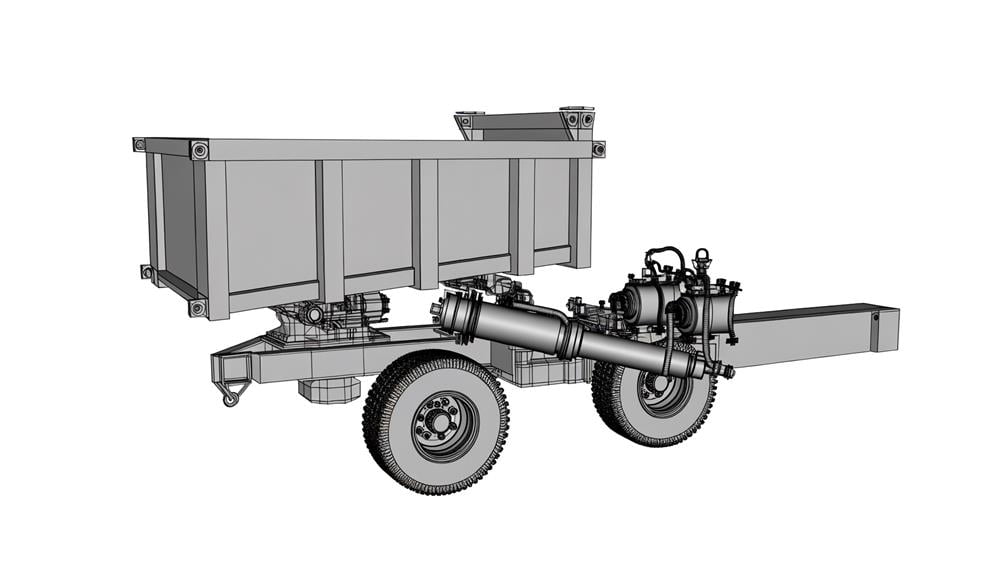

It's estimated that over 70% of all heavy-duty machinery, like dump trailers, rely on hydraulic power. The hydraulic system, particularly the hydraulic cylinder, is the heart and soul of a dump trailer, providing the power to lift, hold, or lower heavy loads.

If the hydraulic cylinder fails, the whole operation grinds to a standstill. But what goes into crafting these essential components? What are the top features to ponder when investing in a hydraulic cylinder?

There's more to these powerhouse devices than meets the eye, and it's worth exploring further.

Key Takeaways

- Hydraulic cylinders, crucial in dump trailers, are manufactured with stringent quality controls, ensuring efficient power transmission and high force output.

- Dump trailers benefit from hydraulic cylinders' precise control, versatility, and ability to handle heavy loads, enhancing operational efficiency.

- LD Machinery Co., LTD. and its subsidiary produce quality hydraulic cylinders with detailed product specifications, suitable for construction machinery including dump trailers.

- The company offers reliable customer service, including a one-year warranty, fast delivery, and 24/7 after-sales online service for their hydraulic cylinder products.

Understanding Hydraulic Cylinder Manufacturing

Since its establishment in 1988, LD Machinery Co., LTD has become a leading figure in the hydraulic industry, specializing in the manufacturing of hydraulic cylinders with stringent quality control measures. The company's use of advanced hydraulic cylinder technology, paired with a deep understanding of industry insights, guarantees quality at every step of the production process.

From raw material testing to final assembly, LD Machinery doesn't let anything slip. Each cylinder is meticulously inspected, making sure that only top-quality brands for seals are used and that the painting process meets the highest industry standards. The company's dedication to quality and precision is what makes them stand out in the industry.

This commitment to excellence, in turn, liberates their customers from the concerns of sub-par products, providing assurance that they're investing in the best.

Safety and Applications of Hydraulic Cylinders

In the domain of industrial operations, understanding the safety precautions when working with hydraulic cylinders is paramount, and these cylinders find extensive applications across various sectors, including construction, agriculture, material handling, and mining.

Hydraulic Cylinder Maintenance is a critical part of ensuring safety. Regular inspections and servicing can prevent malfunctions and accidents. Additionally, Hydraulic Cylinder Innovation enhances the efficiency and safety of applications. Innovations like improved seal design and corrosion-resistant materials increase the longevity and reliability of cylinders.

- Construction: Hydraulic cylinders provide the power to lift heavy loads and move earth.

- Agriculture: They enable the lifting and lowering of agricultural implements, making tasks efficient.

- Material Handling: Hydraulic cylinders are integral to forklifts and cranes, ensuring the safe handling of materials.

- Mining: In this rigorous industry, hydraulic cylinders support various operations, from drilling to material transport.

Advantages and Selection of Hydraulic Cylinders

Understanding the advantages of hydraulic cylinders, it's important to contemplate their role in power optimization and their wide-ranging benefits in industrial operations. The versatility of these cylinders lies in their ability to transmit significant power with precision, facilitating efficient and effective operations.

Hydraulic cylinder maintenance is critical in ensuring peak performance and longevity, while hydraulic cylinder customization allows for the adaptation to various industrial needs.

| Advantages | Selection |

|---|---|

| High power density | Consider force requirements |

| Energy efficiency | Evaluate operating pressure |

| Customizable | Assess physical dimensions |

Seeking liberation from inefficient power systems, one finds freedom in the use of hydraulic cylinders. Their advantages coupled with the ability to customize, they offer a solution that can revolutionize industrial operations.

Detailed Product Specifications

What exactly does the double acting hydraulic cylinder from ZheJiang, China offer regarding specifications and features?

This product is built to deliver efficient power transmission, high force output, and precise control. It's designed to optimize power and enhance the efficiency of heavy machinery.

- Seals: It uses high-quality seals from Hallite, Parker, and Merkel.

- Painting: The cylinder has anti-rust painting for durability.

- Certification: It's ISO9001, SGS, CE, BV, and TUV certified.

- Control: Every cylinder undergoes rigorous control checks for any defects during assembling, and is also tested for leakage.

This product features not only promise efficiency but also cater to a broad market spectrum. The market analysis indicates a robust demand for such high-performing and reliable hydraulic cylinders.

Company Overview and Customer Services

Beyond the impressive specifications of the hydraulic cylinders, the company behind these products, founded in January 2015, also stands out with its global reach, specialized R&D center, and strong commitment to customer service. It prides itself on delivering top-tier company services, focusing on achieving the highest degree of customer satisfaction.

The company offers detailed customer support, with an efficient after-sales service that operates 24 hours a day, 7 days a week. To confirm transparency and maintain trust, the company also provides a detailed FAQ section addressing common customer queries and concerns.

| Company Services | Customer Satisfaction |

|---|---|

| After-sales support available 24/7 | High level of customer trust maintained |

| Detailed FAQ section | Transparency in operations |

| Efficient delivery system | High degree of satisfaction reported by customers |

This technical and analytical approach guarantees customers feel liberated by their choice to invest in the company's hydraulic cylinders.

Frequently Asked Questions

What Are the Potential Safety Risks Involved With Using a Dump Trailer Hydraulic System?

Potential risks with hydraulic systems include high-pressure injuries, burns from hot fluid, and accidents from failing components. Proper hydraulic system training and knowledge of emergency procedures greatly reduce these risks.

How Does the Weather or External Environment Impact the Functioning of Dump Trailer Hydraulic Cylinders?

Extreme weather conditions can affect hydraulic efficiency and cylinder lubrication. Cold temperatures thicken hydraulic fluid, reducing efficiency, while heat can thin it, risking inadequate lubrication. Regular maintenance counters these effects.

Are There Specific Maintenance Routines Recommended for Hydraulic Cylinders Used in Dump Trailers?

Yes, specific maintenance routines are recommended. They include regular cylinder lubrication to reduce friction, and pressure adjustments to guarantee peak performance. Both are essential for extending the hydraulic cylinder's lifespan.

What Should One Do if They Encounter an Issue or Malfunction With the Dump Trailer Hydraulic System?

When facing issues with a hydraulic system, they should first check the hydraulic fluid types used. If system overheating is the problem, they'll need *to contemplate* solutions such as fluid coolers or heat exchangers.

Can the Hydraulic Cylinders in the Dump Trailer Be Replaced or Serviced Individually, or Does the Entire System Need to Be Replaced?

He can service or replace individual hydraulic cylinders in a system. However, consistent issues may indicate larger problems. Cylinder lifespan and hydraulic leaks are key factors in deciding replacement versus individual repairs.

Conclusion

To sum up, hydraulic cylinders are indispensable to heavy-duty operations. They are meticulously manufactured by leaders like LD Machinery Co., LTD and Hangzhou YUEWEI Hydraulic Technology Co., Ltd. These cylinders provide precision and power to the dump trailer hydraulic, enhancing productivity across industries such as construction, mining, and agriculture.

The rigorous quality control measures guarantee their durability and efficiency, making these cylinders an essential selection for heavy-duty machinery.