Much like a well-conducted orchestra, the intricate process of biomass handling requires precision, efficiency, and a deep understanding of each 'instrument's' role. This process, involving the transportation, handling, and dumping of organic materials like wood waste and pellets, is critical in harnessing biomass as a sustainable energy source.

The discussion will focus on the various types of equipment used, their best operation, and the importance of environmental considerations. Yet, there's more to uncover; what about the role of regular maintenance and vendor selection in ensuring smooth operations? Stay tuned to find out.

Key Takeaways

- Various types of self-unloading trucks are employed to transport and dump biomass materials, with specific trucks used based on material type and conditions.

- Dumper structures and control devices are integral for efficient and safe operations, with considerations for cycle times, throughput rates, and specific operation procedures.

- Specialized dumping equipment, including portable dumpers and side tippers, and conveyance systems like belt conveyors, are used to handle and transfer biomass.

- Environmental and maintenance considerations, such as dust control, contamination risks, and proper maintenance procedures, are crucial in biomass handling operations.

Truck Transport and Dumping

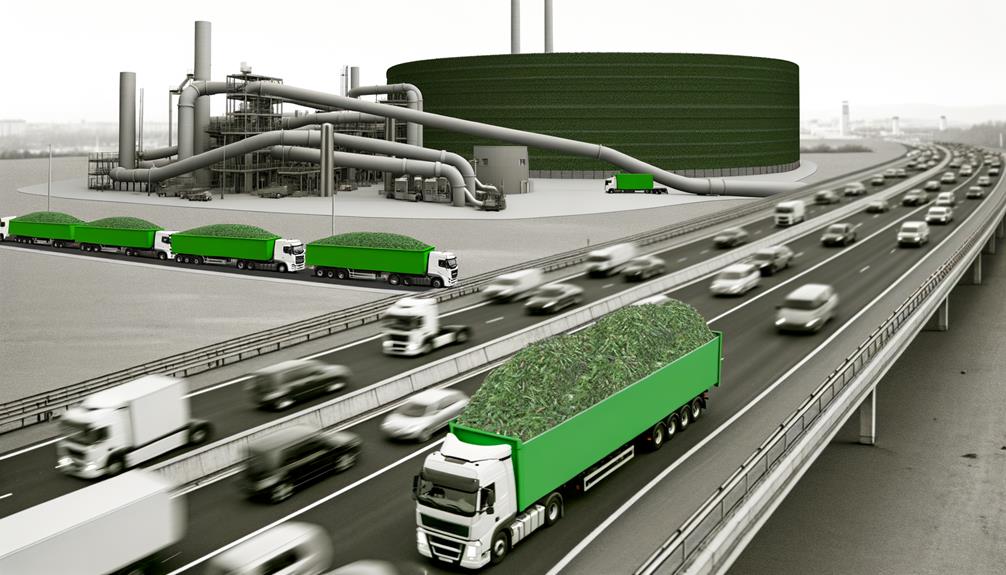

In the domain of biomass handling, raw materials such as wood waste, chips, shavings, and pellets are transported by bulk trucks or railcars. The choice of transport method heavily depends on factors such as material type, weather conditions, distance, and the state of the roads. Truck maintenance is a critical aspect of this process. Ensuring that vehicles are in excellent condition not only promotes efficiency but also reduces the risk of breakdowns, which can be costly.

Moreover, dust control is essential. Biomass materials can generate significant dust during transport, which can pose both environmental and health risks. Hence, measures such as regular truck cleaning and the use of dust suppression equipment are often implemented. These practices demonstrate a strong commitment to sustainability and safety in biomass handling.

Utilizing Truck Dumpers and Handling Equipment

Beyond the transportation of biomass materials, the use of truck dumpers and handling equipment plays a pivotal role in streamlining the process and ensuring operational efficiency. This can be achieved through:

- Truck Dumper Innovations: Companies are constantly innovating to improve the functionality of truck dumpers, enhancing their lifting and dumping capabilities.

- Handling Challenges: Overcoming obstacles such as the handling of diverse biomass materials demands specialized equipment and refined techniques.

- Safety Protocols: Implementing robust safety protocols is essential to protect workers and maintain productivity. These guidelines should address potential risks and provide clear instructions for all operations.

- Operational Efficiency: Employing modern technology and optimized processes can greatly improve the efficiency of biomass handling, reducing time and costs.

Efficient Dumper Operation and Control

To guarantee smooth and efficient biomass handling, mastering the operation and control of dumpers is essential. The process begins with strict adherence to safety protocols; ensuring the operator is well-versed in these is crucial. This not only safeguards the operator but also boosts the overall productivity of the operation.

The cycle times and throughput rates must be optimized for maximum productivity. This involves using control devices that aid in efficient dumper operation. Further, the structures of dumpers also require strong foundations and well-planned control booths.

Role of Specialized Dumping Equipment

While a solid understanding of dumper operation and control plays an important role in biomass handling, it's equally important to ponder the specialized dumping equipment that can greatly enhance productivity and efficiency.

- Portable Dumpers: These are outfitted with outriggers that stabilize the equipment when dumping loads. They're ideal for short-term projects or remote locations where permanent installations aren't feasible.

- Side Tippers: These are specifically designed to handle challenging materials like wastewood. Their unique design allows for efficient unloading, minimizing downtime and enhancing productivity.

- Self-unloading Trailers: These eliminate the need for a separate dumper, providing a streamlined solution for transporting and unloading biomass materials.

- Belt Conveyors: Used in conjunction with hoppers, they efficiently move biomass from dumping stations to storage areas, reducing manual labor and increasing throughput.

With these specialized tools, biomass handling reaches new levels of efficiency and effectiveness.

Environmental and Maintenance Aspects

Managing the complexities of environmental and maintenance aspects in biomass handling, dust control systems and contamination risk mitigation become paramount due to the potential harm to both equipment and the environment. Controlling dust in biomass handling helps maintain equipment longevity and guarantees a healthier environment. Mitigating contamination risks involves proactive measures to prevent pollutants from infiltrating biomass materials.

| Aspect | Importance | Solution |

|---|---|---|

| Dust Control | Protects equipment, enhances air quality | Use dust control systems |

| Contamination Risks | Prevents pollutant infiltration | Implement risk mitigation strategies |

| Maintenance | Ensures longevity, efficiency of equipment | Regular checks, cleaning, repairs |

Environmental and maintenance aspects intertwine, providing a symbiotic pathway for sustainable biomass handling. By prioritizing these elements, we can liberate the biomass industry from potential environmental and operational hazards.

Frequently Asked Questions

What Are Some Safety Measures and Precautions to Consider During Biomass Transport and Dumping Operations?

When considering safety during transport and dumping operations, it's essential to follow transport regulations strictly to avoid biomass contamination. Implementing dust control systems and regular maintenance are also key for safe and efficient operations.

What Are the Costs Associated With the Purchase and Operation of Various Types of Truck Dumpers and Handling Equipment?

In purchasing and operating truck dumpers, costs vary. Factors include the dumper type, maintenance expenses, and biomass storage requirements. They'll need to account for initial purchase, routine upkeep, potential repairs, and storage facility expenditures.

How Does Weather Affect the Operation and Control of Truck Dumpers in Biomass Handling?

Weather greatly impacts truck dumper operations. It's essential for proper dumper maintenance and weather-proofing strategies to guarantee efficient, uninterrupted operation despite harsh conditions. These strategies liberate operators from weather-induced challenges, fostering smoother workflows.

What Are the Potential Impacts of Biomass Handling and Dumping Operations on Local Wildlife and Ecosystems?

Potential impacts on local wildlife and ecosystems include habitat disruption and contamination risks. However, strategies like robust biomass quality control and wildlife protection can minimize these impacts, ensuring harmony between industrial operations and environmental preservation.

Are There Any Specific Training or Certification Requirements for Personnel Involved in Biomass Transport, Dumping, and Handling Operations?

Yes, there're specific trainings for personnel in biomass transport and dumping. Regulations like Biomass Legislation mandate certain certifications. These guarantee safe, efficient biomass storage and diminish environmental impacts. Each country may have different requirements.

Conclusion

Biomass handling is a complex, but essential process in sustainable energy production. Through careful transportation, efficient utilization of trucks and handling equipment, and meticulous dumping methods, raw materials can be effectively managed.

Specialized equipment caters to unique needs, while environmental and maintenance considerations guarantee long-term operational efficiency.

Fundamentally, understanding every facet of biomass handling is fundamental for harnessing the full potential of this renewable energy source.